A. Zahner Company

ZAHNER adopted Dassault Systèmes’ 3DEXPERIENCE platform and its Design for Fabrication on Cloud industry solution experience to fabricate the Chrysalis Amphitheater in Merriweather Park, Maryland.

Architecture as Art

US-based architectural engineering, manufacturing and construction firm, A. Zahner Company, has its roots in the sheet metal fabrication industry. Since it was founded in 1897, the family-owned business has imagined and built some of the world’s most audaciously-shaped architectural metal structures like the Petersen Automotive Museum in Los Angeles. With the emergence of digital technologies in the 1980s, the company began to adopt a more artistic approach to architecture that has won it numerous awards and international acclaim over the years. “3D digital technologies enable us to design more complex geometries; we are no longer limited by two-dimensional drawings,” L. William Zahner, president and CEO at ZAHNER, said. “As architectural projects become more and more complex, technology helps us push the boundaries of what is possible.”

ZAHNER is at the forefront of a shift in architecture to digital construction. “Our company has been using Building Information Modeling and digital definition to improve transparency that reduces errors through a leaner, more streamlined construction process,” L. William Zahner said. “Our biggest challenge in the construction world today is the fact that we’re working within this old paradigm that an architectural project is an iterative process. One group does this, another group does that and then there’s a communication issue that we have to solve to make sure all these groups exchange the right information at the right time. We, as an industry, are not always successful in this area.”

ZAHNER’s Chief Operating Officer Tom Zahner believes the 3DEXPERIENCE® platform is helping ZAHNER close the gap between its current performance and its potential by improving the way structures are designed, engineered and built in three key areas. “First, there’s the ability for people to do the right things at the right time,” Tom Zahner said. “Second, there’s clarity because 3D design speeds decision-making by facilitating comprehension, regardless of what language people speak or what discipline they’re from. Finally, there’s more focus, which suffers when people have to translate data, because they use incompatible software solutions. With this unique platform, they have compatibility and a clear understanding of what everyone needs to do to move projects forward.”

The future has never been more exciting. We have all these capabilities with the 3DEXPERIENCE platform that allow us to push the limits of architecture.

Collaboration is an evolving process

ZAHNER’s management believes that successful projects must have an efficient, collaborative component. “Throughout the life of a project, the collaborative effort changes as you move from the early stages, where design is immature, to the final stages, where you’re actually constructing, executing and closing out a building,” Tom Zahner explained. “Our vision is to make collaboration flexible and nimble enough so that you get as much interaction out of the design team in the very beginning stages as you can at the very end.”

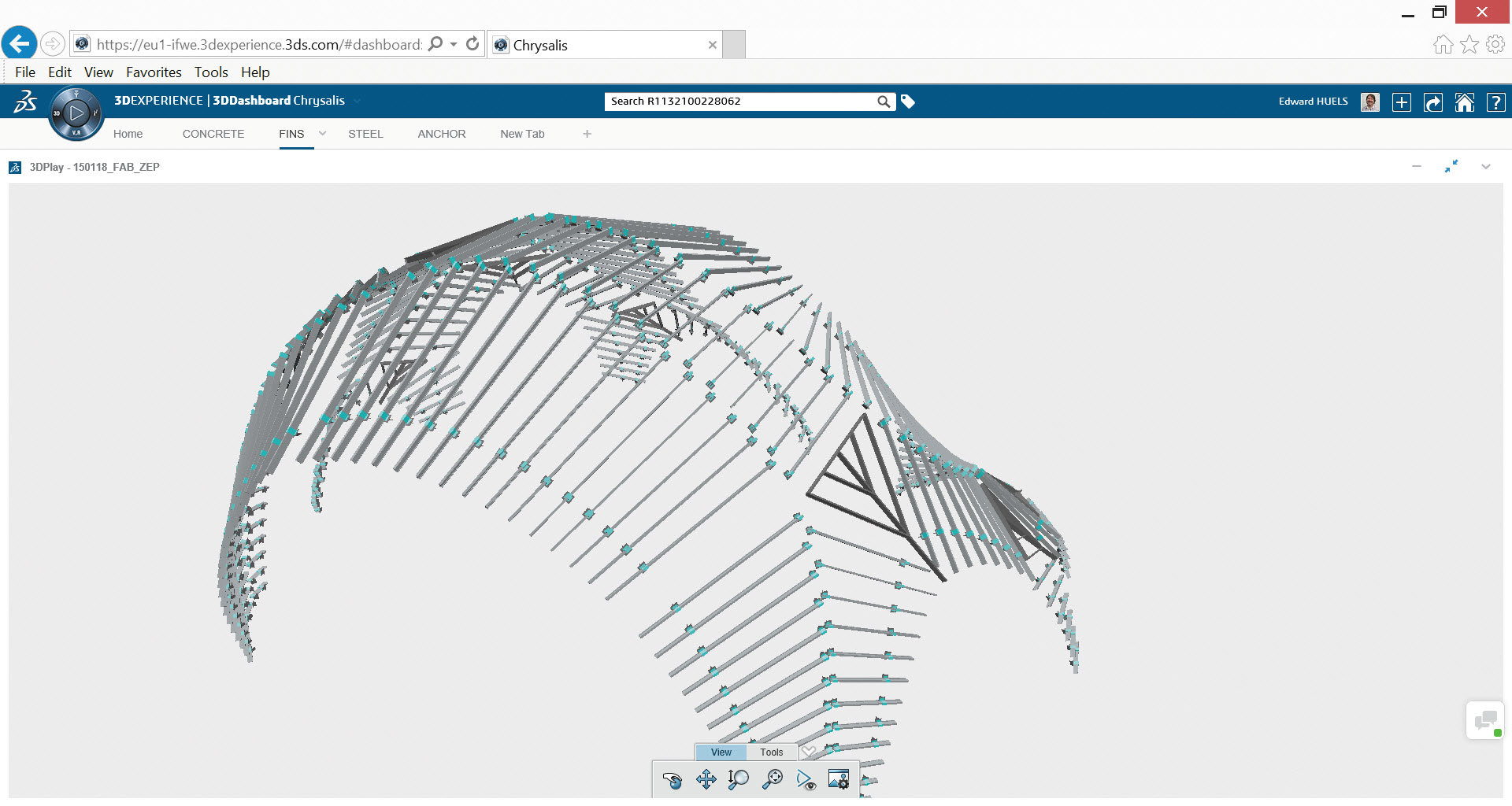

Increased design complexity and the need to streamline communication requires a powerful yet flexible technology that can adapt to any situation. To meet these challenges, ZAHNER adopted Dassault Systèmes’ 3DEXPERIENCE platform and its Design for Fabrication on Cloud industry solution experience, including CATIA for design and ENOVIA for project coordination and collaboration. “We decided to inaugurate the 3DEXPERIENCE platform on the Chrysalis project, a 70-foot tall amphitheater that we’re fabricating in Columbia, Maryland,” Tom Zahner said. “We’ve chosen this project because of the complexity of the parts, which require a powerful design solution like CATIA and a more efficient method of communicating with the different stakeholders due to this complexity.”

Designed by Marc Fornes of The Very Many in New York City, the amphitheater’s geometry illustrates the multifaceted yet artistic side of ZAHNER’s architecture. “The Chrysalis comprises intriguing and complex shapes and surfaces that aren’t limited by Euclidian or rectilinear geometry,” L. William Zahner said. “The outer shell is so complex that when people look at it, they can’t figure out how it was constructed.”

“The challenge is describing to the customer exactly what they are going to receive at the end of the project because it’s not a standard building product,” Shannon Cole, senior project engineer at ZAHNER, said. “There’s not a catalog that somebody goes to and picks out the ‘Chrysalis.’ So one important thing that we always try to do is describe to the customer really early on what they’re going to be getting from us at the end of the day. The 3DEXPERIENCE platform helps us do that in real time.”

The 3DEXPERIENCE platform also enabled all stakeholders to visualize the construct early on to address issues as they arose. “The Chrysalis stage has no walls,” Tom Zahner said. “It has no clear delineation, so navigating yourself around the building is challenging. With the 3DEXPERIENCE platform, you’re able to bring everybody to the site, rotate it around and identify the specific area that’s of concern and get the right people focused on it.

“There were several elements that were not fully designed when we won the bid, and that’s not unusual,” Tom Zahner continued. “However, by using the 3DEXPERIENCE platform, the timeliness of identifying where problems were so the team could focus on a specific area has been invaluable.”

Creating a story

The Chrysalis is a very dynamic project, says Tom Zahner, which requires a flexible platform to quickly and efficiently update all the stakeholders. “As the project matures we need to process information as it comes in and make sure that every stakeholder – the owner (Inner Arbor Trust), the general contractor, suppliers, partners, and design and construction teams – can access it in real time,” Tom Zahner said.

“We’ve used dashboards on this project to be our touch point for providing information to the customer,” Cole said. “As we’re doing design work and receiving drawings from our outside consultants, we post them as mini stories. The customer has access to that, so they are informed every step of the way. We’re giving visibility to what we’re thinking, what we’re designing and what it’s going to look like. It gives our customers a level of comfort and confidence that 2D drawings absolutely can’t do.”

ZAHNER employees often conduct meetings with project stakeholders on a dashboard within the 3DEXPERIENCE platform. “We rely heavily on dashboards during our coordination meetings with architects, owners and designers,” said Jeff Cunningham, advanced manufacturing engineer at ZAHNER. “We post actions that we can consult in real time and discuss during our videoconference calls. If we need to clarify some points, the digital model’s right there, so an engineer can zoom in, make a quick sketch, annotate it and save that in our meeting notes. The information will be there a week or a month later, and can be communicated to someone who didn’t attend that meeting.”

The 3DEXPERIENCE dashboard allows the designers to share information immediately and in an easy-to-follow story format. “We’re able to keep the online story up-to-date versus information getting lost in e-mail exchanges,” Cole said. “A photo of an anchor might be buried 30 messages down, but if I know it’s the most important part, I can ensure it’s the first item seen on the dashboard.”

“The 3DEXPERIENCE platform’s collaborative capabilities provided us with an entirely new and efficient method of communicating between ZAHNER and our project actors, which simplified the elaboration of such a complex structure with extreme accuracy,” L. William Zahner added.

Dashboards also are entirely customizable. “Users can tailor the dashboards to their profession and only visualize the information that they need for their job,” said Kyle Watson, virtual design for construction (VDC) technical specialist at ZAHNER. “It’s so intuitive, when I train new hires, they don’t even wait until I get to the chapter on customizing dashboards; they’re already playing with the widgets and changing the layout. That’s how easy it is.”

Focusing on the right data

ZAHNER also benefits from the platform combining all communication tools, like modeling, spreadsheets and photos, in one place. “The 3DEXPERIENCE platform clears away a lot of noise and lets you focus on what’s really important, which is solving issues within the project rather than fi nding where you put a spreadsheet,” Cunningham said.

“As a designer, the main benefit of using one platform from concept to design to fabrication is that you can track the fl ow of ideas and you don’t lose track of the information about why a certain piece is located here or there,” Cole said. “It makes it easier to see and understand how we got where we’re at.”

“It has huge impact on our work. It’s going to be able to condense our project timelines, and we’ll be able to create projects in a much more streamlined fashion,” Watson added. “I truely believe that working with the 3DEXPERIENCE platform is giving us a huge advantage in the industry.”

Beyond traditional structures

The future is bright for ZAHNER, as they continue to think and build outside of what already exists with the help of the 3DEXPERIENCE platform. “The future has never been more exciting,” L. William Zahner said. “We have all these capabilities with the 3DEXPERIENCE platform that allow us to push the limits of architecture. We can incorporate wild, curved surfaces in our designs and it will be buildable and easier to understand. We plan to extend our use of ENOVIA for part management and purchasing and to adopt SIMULIA for all our structural analysis needs.”

“The types of projects we’re doing today were not possible 20 years ago,” Cole said. “With the 3DEXPERIENCE platform, they now are.”

“ZAHNER, and AEC industry in general, are pushing the envelope on designs,” Tom Zahner said. “Whether its designs due to the artistic nature of the exteriors to designs that incorporate modern technologies on how to heat a building, you need an effective collaboration platform. The 3DEXPERIENCE platform is a perfect opportunity to get everything on the table so that the AEC industry can advance itself into the modern age, where we can continue to blow past barriers that are there because of traditional construction techniques.”

“One of the biggest changes in the future will be the dynamic or kinetic aspect of façades or other constructs,” L. William Zahner said. “This can be how they’re going to change in shape. The 3DEXPERIENCE platform is going to allow you to predict that and know what sort of forces are going to be extended to that shape as it’s moving – something that’s not really easy to do today.

“In effect, the 3DEXPERIENCE platform enables artists, designers and owners to create interesting structures faster, more effectively than ever before,” L. William Zahner continued. “The platform’s digital simulation features enables us to predict the way a structure will evolve over time. We can then incorporate this information into our designs, making them more precise and less expensive to build. Moreover, we can convince our clients that their projects are buildable because we can simulate construction on the digital construct before we even break ground. The possibilities are simply fantastic.”

Focus on A. Zahner Company

A. Zahner Company is an engineering and fabrication company that specializes in the creation of custom art and architectural systems.

Products: Building and structure facades

Employees: 190

Headquarters: Kansas City, Missouri, United States

For more information: www.azahner.com